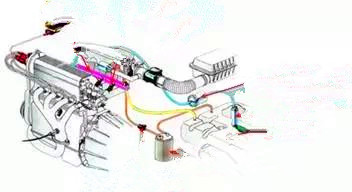

Fuel injection system consists of fuel tank, fuel pump, fuel filter, fuel distributor, injector, oil pressure regulator, fuel steam recovery device and so on.

• Fuel tank is used to store fuel

• Fuel pump continuously sucks the fuel out of the tank to provide fuel system with specified pressure and flow.

• Fuel filter filters the impurities in the fuel.

• Fuel distributor installs injector and delivers high-pressure fuel to each nozzle.

• Injector sprays the fuel into each cylinder after atomizing.

• Oil pressure regulator regulates the fuel pressure by vacuum control.

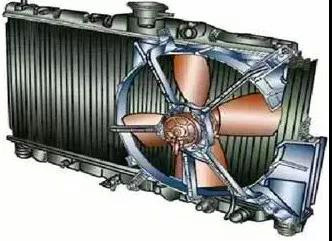

Includes water pump, radiator, expansion tank, cooling water pipe, coolant, thermostat, coolant temperature sensor, cooling fan, liquid level sensor, coolant temperature alarm lamp, and coolant temperature gauge.

• Water pump is installed on the engine to enable the water in the system to complete the circulating work.

• Radiator cools the engine with cooling fan.

• Cooling water pipe is the carrier of the cooling fluid circulation and the connection of various parts.

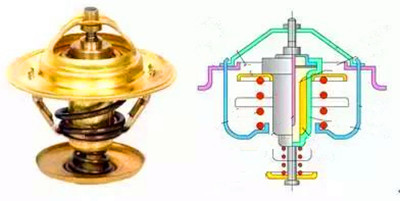

• Thermostat controls the large and small circulation of the automobile cooling system, with large circulation when the thermostat is turned on.

Paraffin is solid at normal temperature, the main valve is fully closed, and the water path leading to the radiator is closed; the auxiliary valve is completely open, and the cooling water from the outlet of the engine cylinder head flows back into the cylinder body water jacket through the water pump for small circulation.

When the engine water temperature rises, the paraffin becomes liquid gradually and the volume increases, forcing the rubber tube to shrink and generating upward thrust on the center rod. Under the reverse thrust of the center rod, the main valve opens gradually and the auxiliary valve closes gradually; When the engine water temperature reaches 80 ℃ or above, the valve is fully open, the auxiliary valve is completely closed, and the cooling water from the outlet of the cylinder head flows to the radiator for large circulation.

When the cooling water temperature of the engine is in the range of 70-80 ℃, the main valve and the auxiliary valve are in a semi-open and closed state. At which time a part of the water carries on large circulation, while the other part of the water carries on small circulation.

• Coolant temperature sensor is used to monitor the current coolant temperature to determine whether the heat dissipation of the current engine is normal.

• Cooling fan cools the coolant.

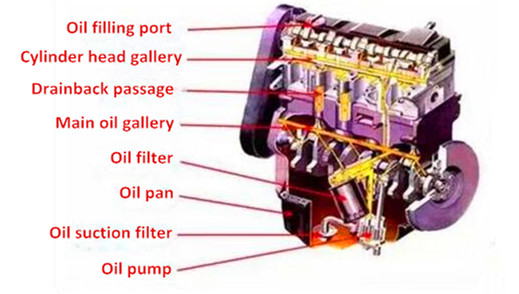

Includes oil pump, suction filter, oil filter, oil pressure switch and oil pressure indicator, etc.

• Oil pump exerts the pressure oil to carry on the lubrication of various parts.

• Suction filter is also called crude oil filter, which filters some of the larger impurities in the oil.

• Oil filter is also called fine oil filter, which further filters out impurities in the oil.

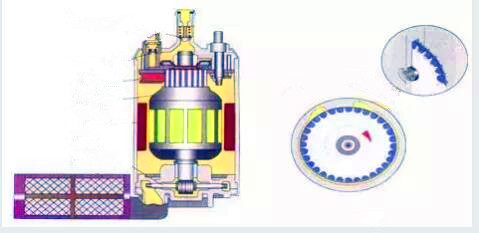

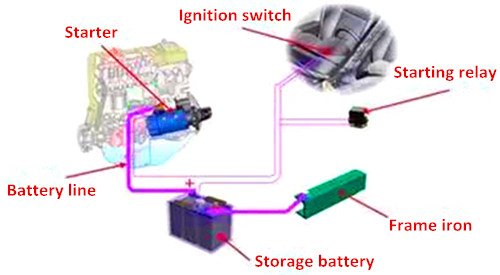

Includes starter, starting switch and starting relay.

• Starter converts the electric energy from the battery into mechanical energy to start the engine.

• Starting switch controls whether the starter works.

• Starting relay protects lines and ignition switch.

Mainly includes air filter assembly, turbocharger, intercooler, intake manifold, intake pipe assembly, air flow sensor and throttle valve assembly.

• Air filter filters the impurities in the air to ensure that the air entering the engine participating in the combustion is clean.

• Turbocharger increases intake pressure to ensures air intake.

• Intercooler reduces the air inlet temperature to ensure more air intake.

• Intake manifold is connected to the transmission pipeline.

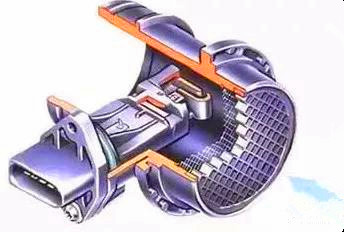

• Air flow sensor converts the inhaled air flow into an electrical signal that is sent to the electronic control unit as one of the basic signals that determine the injection timing.

The air flow sensor converts incoming air flow into electrical signal to the electronic control unit, which is one of the basic signals to determine the injection time.

• Throttle valve controls and monitors the amount of air inflow and indirectly controls the amount of fuel injection.

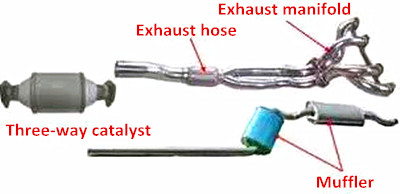

Includes exhaust manifold, three-way catalyst, muffler and exhaust pipe.

• Exhaust manifold is connected to the engine cylinder block and the exhaust gas from each cylinder is confluent into the exhaust manifold.

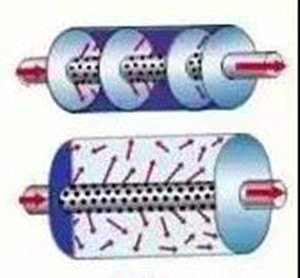

• Three-way catalytic converter is purification unit installed in the automobile exhaust system, which reduces pollution emissions and makes the exhaust emission up to standard.

• Muffler reduces engine exhaust noise and enables high-temperature exhaust gas to be discharged safely and effectively.

• Exhaust pipe discharges the automobile exhaust gas and also connects the exhaust components.

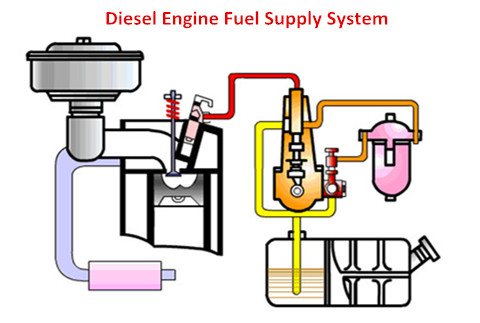

More information about diesel engine at this article: Two Major Mechanisms of Diesel Engine

Copyright © Guangxi Dingbo Generator Set Manufacturing Co., Ltd. All Rights Reserved | Sitemap

Update cookies preferences