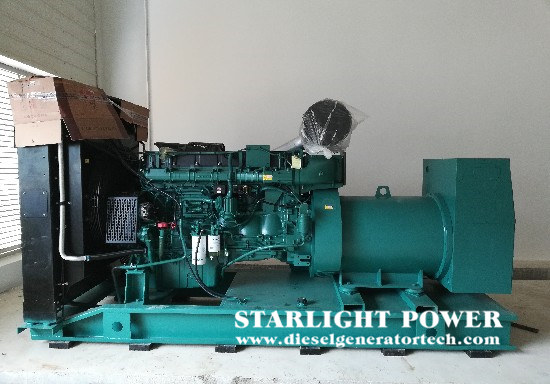

Today, we will briefly introduce the structure of the exhaust turbocharger of Volvo generator.

Working principle of exhaust turbocharger. The exhaust turbocharger consists of two contact parts: turbine and compressor. The turbine inlet is connected with the diesel engine exhaust pipe, and the air compressor outlet is connected with the diesel engine intake pipe. Because the exhaust gas from the diesel engine still has a certain amount of energy, the gas turbine is driven to rotate. At the same time, in order to drive the air compressor to rotate on the same axis, the air compressor compresses the fresh air absorbed by the diesel engine to increase its density, thus increasing the intake pressure and inflation capacity, so as to increase the power of the diesel engine. It can be seen that the exhaust turbocharger is driven by the exhaust gas of the diesel engine, and there is no mechanical transmission relationship between the turbocharger and the diesel engine.

The structure of the exhaust gas turbocharger of Volvo generator: the actual exhaust gas turbocharger is equipped with a support device in addition to the air compressor of the turbine. Sealing device, lubrication system and cooling system. Although the models of exhaust gas turbochargers of Volvo generators are different, their basic structures are similar. One end of the turbine is installed on the flange of the exhaust manifold, and the other end of the air compressor is installed on the intake manifold. The nameplate fixed on the supercharger has part number, serial number, model and other descriptions.

Turbine part: composed of turbine impeller, shaft, turbine shell and other parts. The air compressor impeller is fixed on the exhaust gas turbine shaft with a locknut, and the rotating part of the exhaust gas turbocharger is called the rotor.

Support device: It consists of bearings installed in the middle shell, which are respectively close to the air compressor end and my chat end. It is composed of guard plate, thrust plate, etc. The support device enables the rotor to be reliably positioned on the intermediate shell, limiting the axial and radial movement range of the rotor when it works.

Sealing device: composed of oil seal assembly, gas seal ring, etc. The sealing device at the compressor end mainly seals the high-pressure air in the compressor and prevents the oil in the oil chamber from entering the compressor. The turbine end sealing device prevents high-temperature exhaust gas from entering the oil chamber to ensure oil quality.

Cooling system of lubrication system: therefore, the turbocharger of KTTA diesel engine has oil cooling and lubrication, and the oil circulates through the bearing housing.

The reason why the supercharger uses floating bearing is that when the supercharger speed exceeds 4000r/min, if the non-floating bearing is used, the sliding speed between the shaft surface and the bearing inner surface is quite high, the bearing is easy to wear, and the ordinary sliding bearing is not competent. The bearing made of lead-tin alloy with floating bearing is installed in the bearing housing, and the shaft 3 is supported in the shaft for high-speed rotation. There is clearance between bearings and shafts, between bearings and bearings. The lubricating oil with pressure enters the inner and outer clearance of bearings from the pipe joint at the upper part of the bearing housing. During the operation of the diesel engine, oil film is formed in the internal and external clearance of the bearing, and in the internal and external clearance of the bearing during the operation of the diesel engine, which plays the role of the bearing.

Floating bearings are divided into full-floating bearings and semi-floating bearings. The full-floating bearing rotates at a certain speed, while the semi-floating bearing does not rotate. This time, the bearing often uses an integral floating sleeve, one end of which is a square structure. Under the same conditions, the mechanical loss of semi-floating bearing is less than that of full-floating bearing. Compared with ordinary sliding bearings, floating bearings have the advantages of low temperature, small friction work, reliable operation, good vibration resistance and convenient disassembly and maintenance. The diesel engine (maintenance technology) can have two or four turbochargers. If the diesel engine (maintenance technology) has four turbochargers, the two turbochargers installed on the exhaust manifold are high-pressure turbochargers, and the two turbochargers installed on the bracket are low-pressure turbochargers.

As a professional diesel generator manufacturer, we always insist on using first-class talents to build a first-class enterprise, create first-class products, create first-class services, and strive to build a first-class domestic enterprise. If you would like to get more information welcome to contact us via [email protected].

Copyright © Guangxi Dingbo Generator Set Manufacturing Co., Ltd. All Rights Reserved | Sitemap

Update cookies preferences