Exhaust gas turbocharger, the most commonly used method of diesel generator turbocharging, is called exhaust gas turbocharging system in diesel generator set. Today we will focus on sharing the working principle of exhaust gas turbocharger.

1.The working principle of exhaust gas turbocharger

Exhaust gas turbocharger is a turbocharger driven by exhaust gas energy from diesel engine, which compresses air and then feeds it into cylinder. After diesel engine turbocharging with exhaust gas turbine, the output power of diesel engine can be increased by more than 30% to 100%. At the same time, it can also reduce the unit power quality, reduce the shape size, save raw materials, reduce fuel consumption, increase the torque of diesel engine, increase the load charge capacity, and reduce the pollution of exhaust to the atmosphere. So it has been widely used.

2.The structure of exhaust gas turbocharger

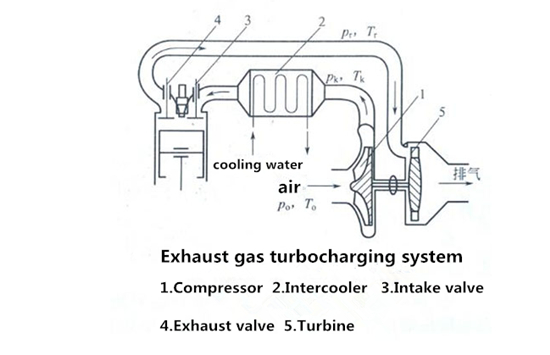

The structure of exhaust gas turbocharging system in diesel generator is shown in the figure.

The exhaust pipe of diesel engine is connected to the volute of the turbocharger. The exhaust gas with high temperature 500℃ to 600℃ and certain pressure from the diesel engine enters the nozzle ring through the volute, and the channel area of the nozzle ring gradually decreases from large to small. Therefore, it can be achieved: although the pressure and temperature of the exhaust gas are decreasing, but its flow rate is constantly increasing. This high-speed exhaust gas impacts the turbine in a certain direction to let pressure, temperature and speed of turbine high-speed rotation exhaust gas increase, then the faster the speed of the turbine. The exhaust gas through the turbine is finally discharged into the atmosphere.

3.Turbocharging form of exhaust gas turbocharger

The exhaust gas turbocharger can be divided into two types according to the direction of the air flow entering the turbine: the axial flow type and the runoff type.

The structure of the runoff turbocharger is shown in the figure.

It mainly consists of volute, nozzle ring, turbine and rotor shaft etc. When runoff turbocharger works, the exhaust gas from the diesel engine enters the volute of the turbocharger and flows vertically along the axis of the turbocharger rotor shaft, the impeller is forced to change the flow direction along the deaf curved passage. Under the action of centrifugal force, the particles of air flow are projected to the N side of the blade, and the pressure increases while the relative velocity decreases; the relative velocity on the convex side of the blade increases while the pressure decreases.

When an axial-flow turbocharger works, the exhaust gas from the diesel engine enters the volute of the turbocharger, and the airflow flows along the axis of the turbocharger's rotor axis, so it is called an axial-flow turbocharger.

According to whether the pulse energy of exhaust gas in exhaust pipe of diesel engine is used or not, the exhaust gas turbocharge can be divided into constant pressure type and pulse type.

Constant-pressure exhaust gas turbocharger is to connect the exhaust manifold of all cylinders of a multi-cylinder diesel engine to an exhaust manifold and then to the turbocharger shell. The exhaust gas is directed to the whole nozzle ring along a single volute intake passage with an average pressure. This turbocharger is often used in high-power and high-pressure diesel engines.

The schematic diagram of the exhaust system of the pulse exhaust gas turbocharger is shown in the figure.

Take six-cylinder diesel engine as an example, the ignition sequence is 1-5-3-6-2-4, usually, the exhaust passage of 1,2,3 cylinders are connected to an exhaust manifold, along an inlet port on the volute to another half ring nozzle ring, so that this structure can make full use of the pulse energy of exhaust gas.

The main performance index of the exhaust gas turbocharger is the air pressure rise ratio, referred to as the pressure ratio. It is expressed as the ratio of the compressor outlet air pressure “pk” to the compressor inlet air pressure “p1”, that is nk=pk/p1.

The greater the air pressure at the compressor outlet, the greater the air density entering the cylinder. Turbochargers can be divided into three types according to pressure ratio: low turbocharger nk <1.8, medium turbocharger nk=1.7~2.5 and high turbocharger nk>2.5.

For medium turbocharger nk>1.8, in order to reduce the air temperature at the outlet of the compressor and increase the air density entering the cylinder, a low and medium turbocharged runoff pulsed exhaust gas turbocharger is widely used in diesel engines. High turbocharged diesel engine has became the development trend.

Starlight power manufacturer focuses on providing high quality power generator, cover Cummins, Volvo, Perkins, Deutz, Yuchai, Shangchai, Doosan etc. If you have purchase plan, welcome to inquiry us by sales@dieselgeneratortech.com, or call us by +86 134 8102 4441 directly.

Copyright © Guangxi Dingbo Generator Set Manufacturing Co., Ltd. All Rights Reserved | Sitemap

Update cookies preferences