The fuel injector of Cummins diesel generator is one of the important components in the fuel system of Cummins diesel generator, and its working condition and performance directly affect the normal operation of Cummins diesel generator. When the atomization of the fuel injector does not meet the standard, the fuel in the cylinder cannot be completely burned, which not only affects the normal operation of the Cummins diesel generator power, but also directly causes fuel waste. Over time, carbon deposition increases, and lubricating oil is also diluted, greatly affecting engine performance. Regular inspection and calibration of the fuel injectors of Cummins diesel generators is a condition to ensure their safe operation. The manufacturer of Cummins diesel generators reminds users to do a good job of fuel injector calibration in daily life. The calibration content of the fuel injector for Cummins diesel generator is as follows:

The fuel injector of Cummins diesel generator is the connecting piece on the high-pressure oil pipe of the fuel injection pump, located on the cylinder head, which is the fuel injector. To adjust it to the standard pressure with the standard pressure gauge, the method of correcting the injector is to observe the spray condition of the injector and correct it.

Adjustment of fuel injector opening pressure: Use a wrench to loosen the fuel injector nut, and use a screwdriver to screw in or select the adjusting screw of the fuel injector to adjust the compression force of the spring to achieve the specified fuel injection opening pressure for each type of fuel injector. Screw in the adjustment screw, the opening pressure of the fuel injector will increase, otherwise it will decrease. After adjustment, tighten the pressure regulating nut.

The spray test of fuel injection nozzle shall meet the following requirements: the fuel sprayed shall be in the form of mist, uniform and dense in parts, without obvious splashing oil particles, continuous oil droplets or local non-uniformity of concentration and dilution, obvious at the beginning and end of the application of fuel injection, with special crisp sound, and the nozzle shall be free of oil dripping, but allowed to be wet. The cone angle of spray spray beam direction is about 15-20 degrees.

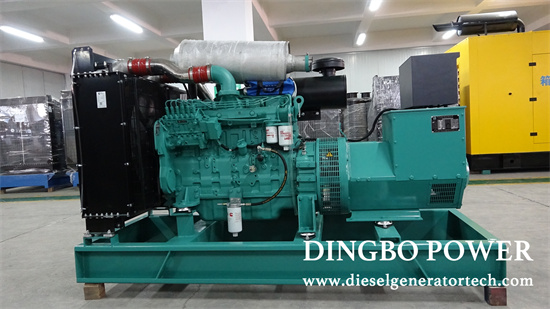

Guangxi Dingbo Generator Set Manufacturing Co.,Ltd was founded in 1974 and is one of the earliest manufacturers of generators and diesel generator sets in China. The company has a registered capital of 218.88 million yuan. The company covers an area of 86,000 square meters and a building area of 55,000 square meters. There are more than 660 employees, including 456 professional technicians and 106 senior technicians. It has 46 sales and service outlets nationwide. The main products are diesel engines, generator sets, and diesel generators, providing users with a one-stop service of design, supply, debugging and maintenance at any time. Dingbo has always insisted on using first-class talents, building first-class enterprises, manufacturing first-class products, creating first-class services, and making every effort to build a first-class domestic enterprise. If any question please feel free to visit our website https://www.dieselgeneratortech.com/ or send email to [email protected].

Copyright © Guangxi Dingbo Generator Set Manufacturing Co., Ltd. All Rights Reserved | Sitemap

Update cookies preferences